Braketex

Tribco Braketex is a 100% Kevlar fiber composite material which offers a high wear resistance and low opposing surface wear. Braketex contains no metal, abrasives, or asbestos. It can be used in wet or dry applications.

Dynamic dry coefficient of friction: 0.36

Dynamic wet coefficient of friction: 0.10 to 0.15

Clutchtex

Tribco Clutchtex is a 100% Kevlar fiber composite material which offers a high wear resistance and low opposing surface wear. It has excellent shock resistance and very low thermal conductivity. Clutchtex contains no metal, abrasives, or asbestos.

Dynamic dry coefficient of friction: 0.36

Dynamic wet coefficient of friction: 0.10 to 0.15

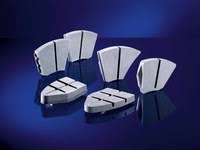

Disc Brake Linings

Bremskerl disc brake linings are made of high quality materials which help evenly distribute energy across the entire disc surface. This helps reduce wear, increasing both linings and rotor life.

Typical applications: Mobile cranes, overhead cranes, public transit, trains

Drum Brake Linings

Bremskerl drum brake linings are available in a variety of sizes and designs to fit your equipment. Bremskerl produces high quality, asbestos-free friction materials with reduced wear rates.

Typical applications: Mobile cranes, overhead cranes, public transit, trains

Flexible Molded

Scan-Pac 230AF and 232AF flexible molded sheeter linings are recommended for light to medium duty clutch and brake applications. Green Gripper Aramid (GGA) has a high aramid content, which allows it to be used for demanding tensioning applications. It contains no metal, giving it low abrasion. GGA is flexible when uncured, and rigid when cured.

Coefficients of friction: 0.27 to 0.48

Typical applications: Industrial clutches and brakes, unwind and rewind stands, tensioning units

Flexible Woven

Scan-Pac’s woven friction materials are flexible and available in a variety of widths and thicknesses. These non-asbestos materials offer a consistent high friction level and good wear rate. Green Gripper Woven (GGW) is a versatile material for heavy-duty industrial applications. Gemini Woven is a more affordable option that doesn’t sacrifice performance.

Coefficients of friction: 0.50 to 0.51

Typical applications: Industrial brakes and clutches, winches, elevators, commercial fishing boats

Rigid Molded

Scan-Pac offers a wide variety of rigid molded friction materials. Scan-Pac offers flat sheets, molded brake blocks, and custom molded parts. Between the RF and Gemini series, the Rowland Company can help identify a rigid molded material to fit your needs. All Scan-Pac materials are asbestos-free.

Coefficients of friction: 0.11 to 0.63

Typical applications: Industrial brakes, punch presses, PTO’s, overhead cranes

Sintered

Scan-Pac sintered friction products are designed to operate in applications where high energy dynamic stopping produces extreme heat. Good thermal conductivity is achieved with high concentrations of metallic fibers. Custom shapes, sizes, and formulations are available to best suit your application.

Coefficients of friction: 0.39

Typical applications: Agricultural machinery, construction machinery, aircraft

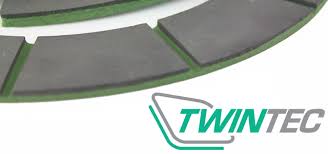

Twintec Materials

Bremskerl Twintec technology consists of an elastic underlayer with a friction lining surface. This provides higher dynamic friction coefficients while reducing lining wear by as much as 80%. Twintec can be combined with almost any Bremskerl material.