Disc Couplings

Disc couplings use flexible diaphragms to accommodate misalignment. There are no wear parts, so lubrication and maintenance aren’t required.

Fluid Couplings

As the name implies, fluid couplings are filled with fluid. This allows them to deliver a soft start while limiting the initial load on your motor.

Torsional Couplings

Torsional couplings are torsionally flexible and can also account for radial, axial, and angular misalignment. These dampen vibration, protecting your driveline and increasing the life of downstream equipment.

Gear Couplings

Gear couplings use gear teeth to accommodate misalignment. They have large torque capacity in a small envelope. Gear couplings can be mounted horizontally or vertically and have minimum backlash.

Jaw Couplings

Jaw couplings feature an elastomer or spider sandwiched between two hubs. These couplings are easy to install and are failsafe in that they’ll still transfer torque even if the elastomer fails.

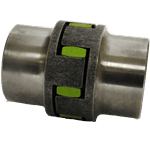

Grid Couplings

Grid couplings feature two hubs jointed by a flexible steel grid. This allows them to reduce vibration and cushion shock loads.