Brake Drums

The Rowland Company supplies high quality brake drums for mobile cranes. A variety of sizes and bolt patterns are available to match your crane.

Brake Shoes and Springs

The Rowland Company offers brake shoes, linings, and springs from OEM-approved vendors. Various rivet patterns are available to match your existing shoes. We also have an exchange shoe program for used cores.

Caliper Discs and parts

The Rowland Company supplies caliper disc and parts for mobile cranes that use disc brakes. These parts deliver the same high quality that you expect from our drum brake parts.

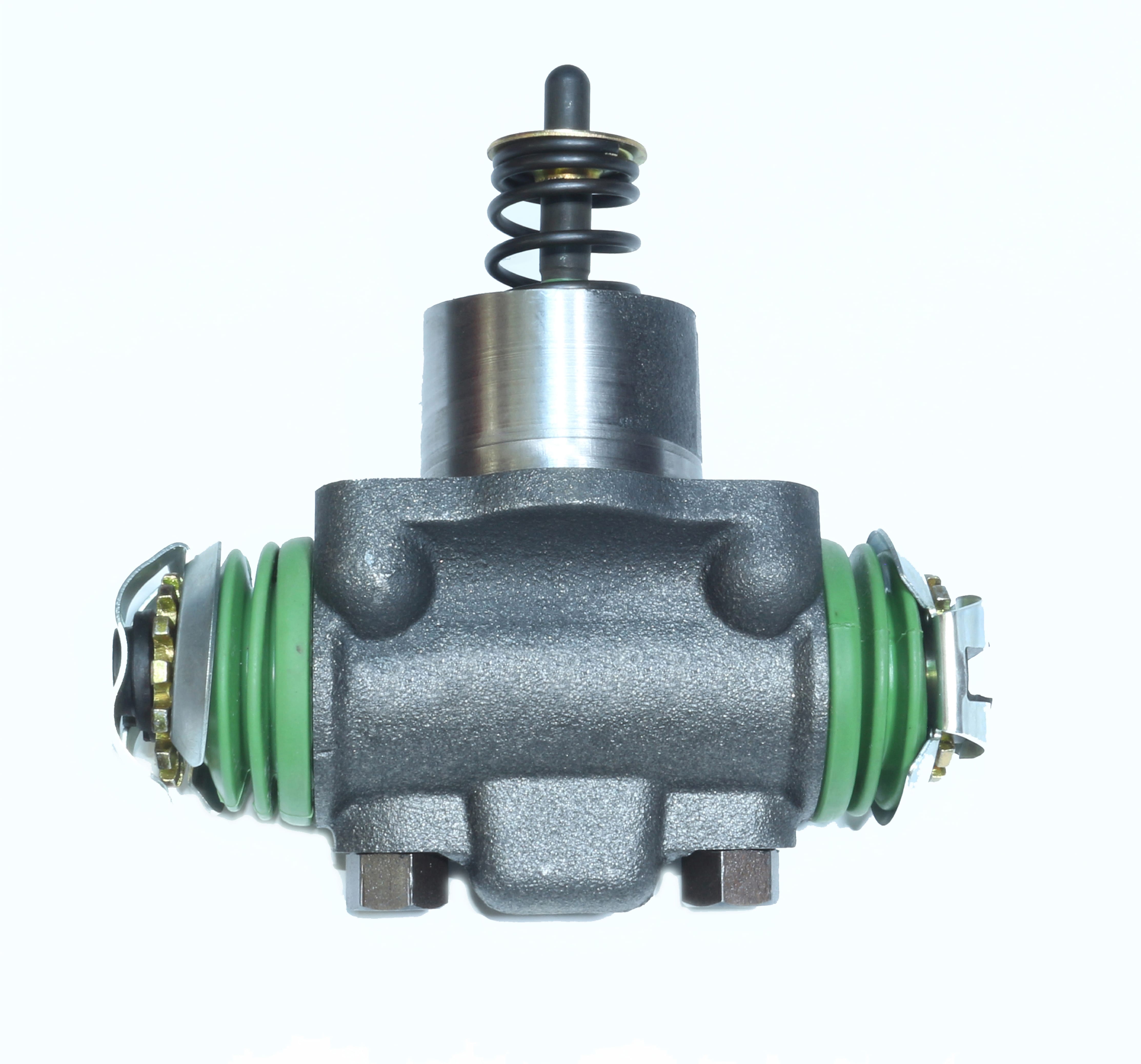

Expanders and parts

Expanders are available for both simplex and duplex configurations. We also provide expander parts like seal kits and adjuster kits.